Innovations in Auto Accessories: How Injection Mold China Transforms Automotive Part Design and Manufacturing

The automotive industry is undergoing a significant transformation, driven by technological advancements and innovative manufacturing techniques. At the forefront of this change is the role of injection mold technology from China, a key player in reshaping how automotive parts and accessories are designed and manufactured. This article explores the impact of injection mold China on the automotive sector, particularly in the realm of auto accessories.

The Impact of Injection Mold Technology on Auto Accessories

Injection mold China has revolutionized the production of automotive accessories, bringing forth unprecedented levels of precision, efficiency, and design flexibility. This technology allows for the creation of complex geometries and intricate designs that were once deemed impossible or too costly to produce. As a result, modern vehicles are equipped with accessories that are not only aesthetically pleasing but also functionally superior.

Advantages of Using Injection Molded Parts in Automotive Manufacturing

The utilization of injection molded parts in automotive manufacturing offers numerous advantages. These include reduced production times, lower costs, and the ability to use a wide range of materials. Injection mold China has enabled manufacturers to produce high-quality parts consistently and at scale, which is crucial in meeting the ever-growing demand for innovative auto accessories.

Enhancing Vehicle Performance and Aesthetics

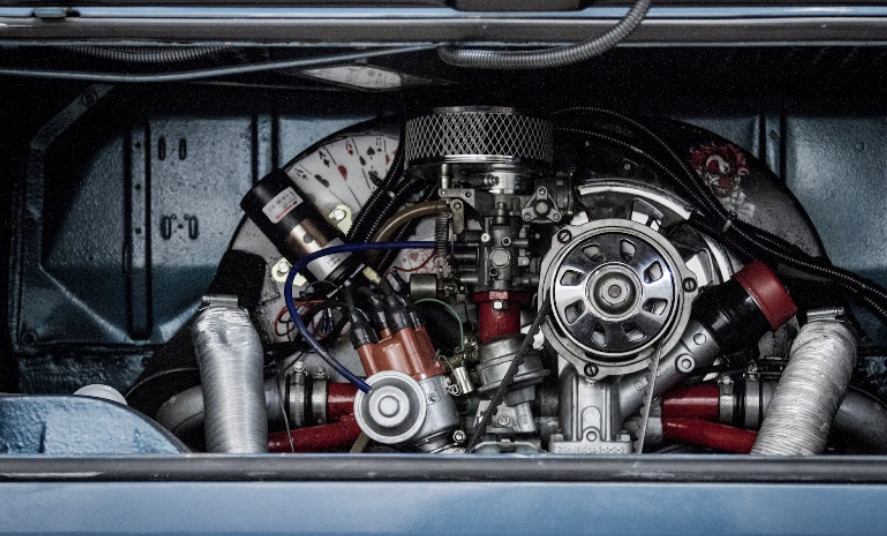

Injection mold technology has a significant impact on both the performance and aesthetics of automotive accessories. By using advanced materials and precision molding techniques, manufacturers can produce parts that are lighter, stronger, and more durable. This not only enhances the performance of the vehicle but also contributes to its overall aesthetic appeal.

The Crucial Role of Plastic Injection Moulding Companies

Plastic injection moulding company is at the heart of this transformation. These companies collaborate closely with automotive manufacturers to develop and produce custom parts that meet specific requirements. Through their expertise and use of advanced injection molding technologies, these companies are essential in driving innovation in the automotive accessories market.

Future Trends in Automotive Accessory Design and Manufacturing

Looking to the future, injection mold China will continue to play a pivotal role in the automotive industry. Emerging trends such as the integration of smart technology into auto accessories and the increasing demand for environmentally friendly materials are likely to shape the direction of future innovations. Injection molding is well-positioned to meet these new challenges, offering solutions that are both technologically advanced and sustainable.

In conclusion, injection mold technology from China has significantly transformed the automotive part design and manufacturing landscape. It has enabled the production of innovative, high-quality accessories that enhance both the performance and aesthetics of vehicles. As the automotive industry continues to evolve, the role of injection mold China and the expertise of plastic injection molding companies will remain crucial in shaping the future of automotive design and manufacturing.